We also suggest taking courses in Lean Six Sigma in IT/Healthcare based on your domain. You’ll also learn to use the statistical Minitab tool to enable effective statistical analysis for projects.Īfter completing these three courses, you will be prepared for becoming a Lean Six Sigma Black Belt, which is the final step to becoming a Lean Six Sigma expert and validating your ability. Fisher College of Business has teamed with MoreSteam, a provider of online Lean Six Sigma training, to provide a more flexible and affordable alternative to.

#Lean six sigma how to#

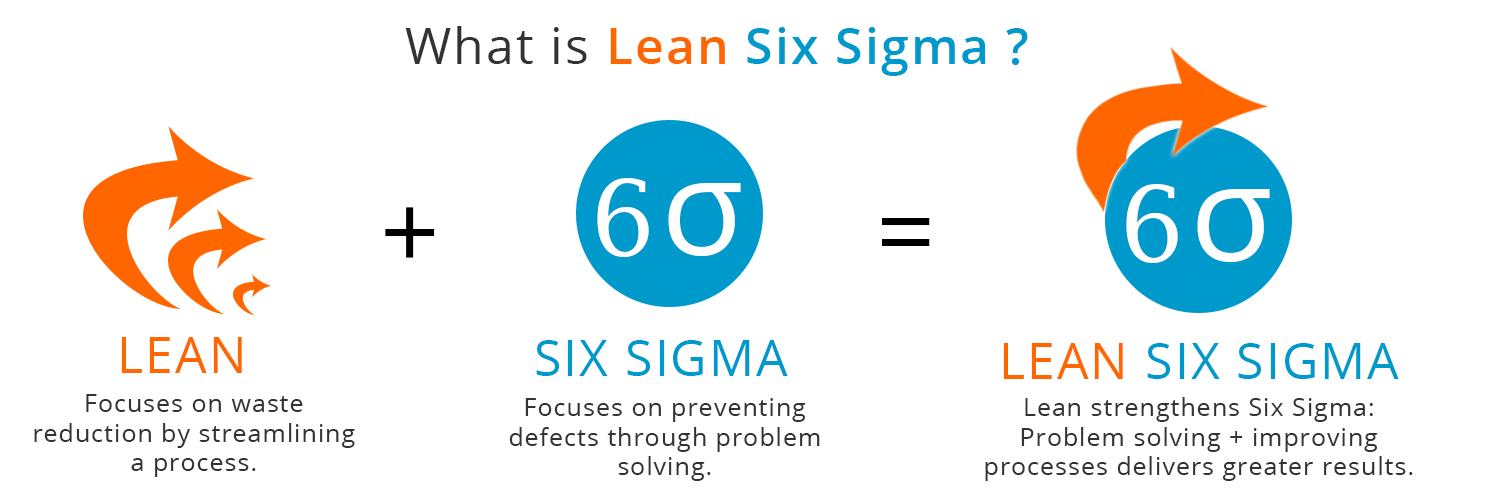

The next stage focuses on the Lean Six Sigma Green Belt, which explains the core principles of Lean Six Sigma, how to implement quality projects and specific industry applications. The Lean Management course is the foundation for this master’s program and shows you how to optimize end-to-end processes to increase quality and drive maximum value in any business. This program provides training in Six Sigma principles including green-belt, black-belt I and II, lean operations, and methodologies for process improvement. Combining the waste-fighting measures of Lean practices, with the variation and defect-reducing techniques of Six Sigma, the Certificate in Lean Six Sigma can. This course positions you to take the lead in quality management projects. As organizations strive for continuous improvement, they seek management professionals that can employ problem solving and business know-how to enhance internal processes. Six Sigma focuses on reducing process variation and enhancing process control, whereas lean drives out waste (non-value added processes and procedures) and.

The Lean Six Sigma Expert Masters Program is aimed at helping you master Lean and Six Sigma principles and methodologies. Purdue University delivers a best-in-class online Lean Six Sigma (LSS) certificate program for students with a range of career objectives and level of. Six Sigma (6) quality is a term generally used to indicate a process is well controlled (within process limits 3 from the center line in a control chart, and requirements/tolerance limits 6 from the center line).

0 kommentar(er)

0 kommentar(er)